Industrial Bulk Plastic Containers: Case Studies From Leading Industries

Wiki Article

A Comprehensive Guide to Selecting the Right Mass Containers for Ideal Storage Space and Transportation

Picking the ideal mass containers is a vital decision for organizations entailed in storage space and transportation. Various elements affect this choice, including material compatibility and size demands. Different sectors have one-of-a-kind needs that need to be fulfilled to guarantee security and efficiency. Recognizing these elements can greatly affect logistics and product stability. The adhering to sections will certainly discover vital factors to consider and finest methods carefully, exposing what really matters in container selection.

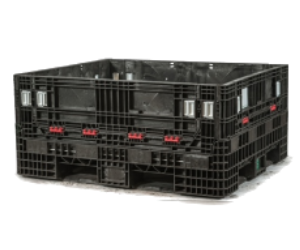

Recognizing Various Kinds of Bulk Containers

Bulk containers act as crucial tools in the storage space and transportation of numerous products, ranging from liquids to solids. These containers can be found in varied kinds, each created for specific applications. Common types include Intermediate Bulk Containers (IBCs), which are perfect for delivering fluids, granules, or powders. Totes, one more variation, appropriate for both solids and liquids and can be stacked for effective storage space. Additionally, mass bags, frequently made from woven material, are used to manage dry bulk materials. For strong materials, bulk bins offer strong, stackable options that maximize space. Each kind of bulk container serves an unique function, assisting in efficient motion and storage space, while guaranteeing safety and security and conformity with industry requirements. Recognizing these alternatives is important for reliable logistics management.Benefits and Drawbacks of Common Bulk Container Options

When assessing mass container choices, it is crucial to consider both their advantages and negative aspects. As an example, inflexible containers, such as steel or plastic bins, use toughness and security against environmental elements, yet they can be heavier and much less versatile relating to storage space. On the various other hand, versatile containers, like mass bags, are light-weight and very easy to manage; however, they may not give the exact same degree of security for sensitive materials. Furthermore, some containers are made for particular products, which can boost efficiency but limit flexibility. Ultimately, the option of mass container depends on balancing these downsides and benefits to satisfy the certain storage and transportation requirements of the products entailed.Secret Factors To Consider for Selecting Bulk Containers

Picking the ideal mass container needs careful factor to consider of a number of crucial factors, as the choice can considerably influence both performance and safety throughout storage and transportation. The product of the container ought to line up with the nature of the items, making certain compatibility to protect against contamination or deterioration. Next, the container's size and capability have to match the volume of products being saved or delivered, enhancing room use. In addition, the weight of the container is necessary for both handling and transportation prices. Toughness and resistance to ecological elements are necessary for preserving item stability. Ultimately, conformity with market regulations and requirements should be verified to prevent legal repercussions (Plastic Bulk Containers). By assessing these factors, companies can go to the website make enlightened choices that boost operational performanceIndustry-Specific Mass Container Needs

Different markets enforce certain demands for bulk containers based upon the nature of the materials dealt with and the governing landscape they run within. For instance, the food and drink sector mandates containers that are certified with health regulations, guaranteeing they are conveniently cleanable and safe to stop contamination. On the other hand, the chemical market usually needs containers that can stand up to destructive materials, necessitating products like high-density polyethylene or steel. In drugs, mass containers must follow rigid standards to protect item honesty and assurance traceability. In addition, markets such as agriculture may concentrate on containers that assist in oygenation or dampness control, while the construction sector might focus on resilience and load-bearing ability. Each requirement mirrors the distinct obstacles and conformity demands of the corresponding sector.

Ideal Practices for Keeping Item Honesty During Storage and Transport

Preserving product honesty during storage and transportation is crucial, as also small mishandling can lead to significant losses or quality destruction. To ensure excellent conditions, temperature level and humidity levels need to be closely kept track of, especially for delicate materials. Utilizing ideal mass containers developed for certain products is vital, as these containers provide essential protection versus contamination and physical damage. Routine assessments of containers and storage space facilities can help determine prospective concerns before they rise - Shop Bulk Plastic Containers. Additionally, proper labeling and paperwork streamline the taking care of procedure, minimizing the threat of errors. Educating employees in ideal techniques for dealing with and carrying products even more safeguards stability, ensuring that products come to their location in the designated problem. Executing these This Site finest techniques can substantially improve general performance and dependabilityFrequently Asked Questions

What Are the Prices Connected With Bulk Container Rental Versus Acquisition?

How Can I Tailor Bulk Containers for Particular Products?

To tailor bulk containers for particular products, one can customize products, dimensions, and attributes such as ventilation or insulation. Branding alternatives, shade coding, and identifying additionally improve performance and identification for effective storage and transportation.Exist Eco-Friendly Mass Container Options Available?

What Is the Ordinary Lifespan of Various Bulk Containers?

The typical life expectancy of bulk containers differs commonly; plastic containers last 5-10 years, metal choices can last 10-20 years, while wooden containers commonly have a lifespan of 3-7 years, relying on usage and upkeep.How Do I Make Certain Compliance With Regulations for Mass Container Usage?

To ensure compliance with guidelines for bulk container usage, one have to consistently examine and understand applicable regulations, preserve proper documents, conduct security audits, and implement training programs for staff members dealing with these containers. Industrial Bulk Plastic Containers.Mass containers serve as crucial tools in the storage space and transportation of numerous products, varying from liquids to solids. Each type of mass container serves a distinctive function, promoting effective activity and storage, while making certain security and conformity with industry criteria. Various markets enforce particular needs for bulk containers based on the nature of the materials took care of and the regulatory landscape they operate within. Making use of proper mass containers created for particular items is essential, as these containers provide required security versus contamination and physical damages. To customize mass containers for details products, one can modify products, dimensions, and attributes such as air flow or insulation.

Report this wiki page